The project aims at quantitatively characterizing and modeling the behavior of geophysical granular flows with a particular emphasis on the effect of substrate properties like roughness and its interplay with the granular material grainsize on the flow characteristics. The latter include flow velocity, thickness and internal structure, which are all factors contributing to the dynamic impact that these flows can have on the territory, human beings and infrastructures.

As such, the proposed research will serve as a pillar to improve our understanding of the mobility of these flows and consequently our ability to predict the areas most likely to be inundated in geological settings where these flows occur and their impact.

Therefore, our proposal is embedded into the wider area of natural disaster risk management through its reduction, for which we act on the hazard quantification component.

Specifically, we want to fulfill the following objectives:

1. quantify the effect of substrate roughness on both the bulk flow properties (thickness, flow-front speed, internal fabric) and the granular flow properties vertical profiles at the wall.

2. Verify the generation of pore pressure in situations in which the granular material is not initially fluidised before it starts moving in a large-scale flume. If a pore pressure is generated, we aim at quantitatively relating this important parameter, which can significantly increase the flow propagation, to the wall and granular material properties, eg, wall roughness, particle size distribution, flow thickness. To our knowledge, it is the first time that pore pressure generation in initially not-fluidized flows is investigated at a large scale, using natural material of varying size and density and with an attempt to find a quantitative relationship between the pore pressure and the substrate and particle properties.

3. Validate and improve both complex numerical models working at the particle-wall scale and models designed to simulate the bulk flow scale that are routinely used for hazard applications; define the most appropriate rheological parameters and scaling laws for these parameters as a function of the most important physical properties.

To achieve these, two research units (RU1 led by University of Bari and RU2 led by University of Calabria) will integrate large-scale flow experiments by using and further enhancing an existing state of the art facility and numerical modeling of the experiments.

The project objectives will be achieved by undertaking work organized in three work packages.

In particular, the first two work packages are intimately interconnected and designed to achieve the three main scientific objectives listed above. The third work package deals with outreach and dissemination of the results and as such will run simultaneously to the first two.

- WP1 Large-scale experiments: the boundary control on the dynamics of complex granular flows (Leader: RU2)

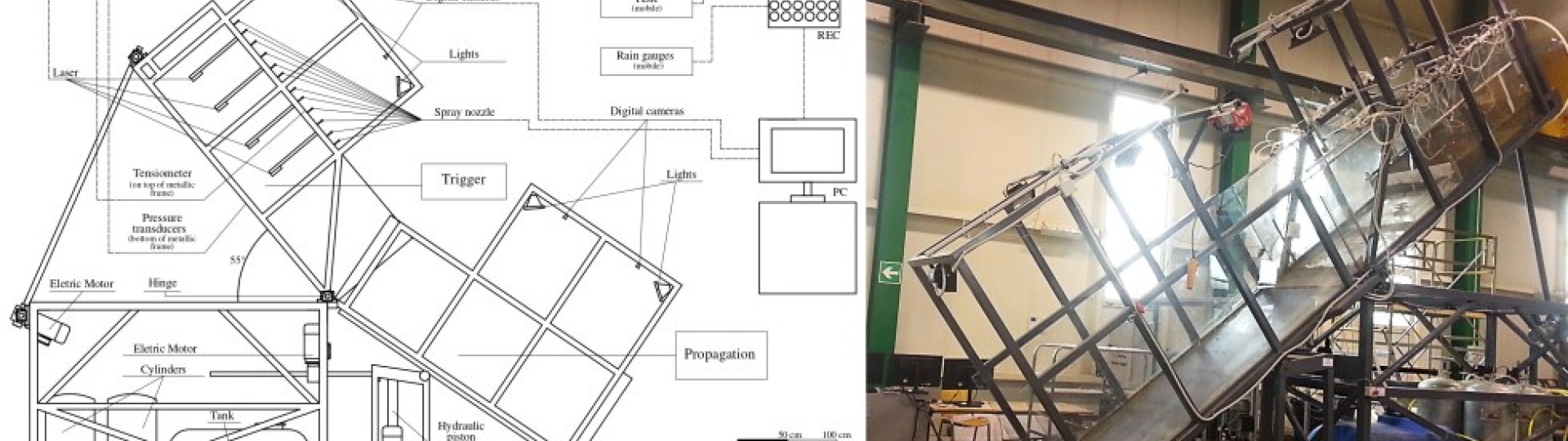

In this work package we will carry out large-scale experiments on dry granular flows in a state-of-the-art flume already available at Università della Calabria. The device was originally designed and built to provide a valid tool useful for reproducing to scale natural processes like landslides and debris flows, with a particular emphasis on the triggering mechanisms. In fact, the flume makes it possible to reproduce physical and spatial characteristics of the phenomenon and the boundary conditions that control the dynamics of the processes and allows, at the same time, evaluating the effects on the processes linked to the different representation scales.

It is currently equipped with a system of sensors to measure the main physical parameters that control deformation and failure processes, a video recording system, lasers to measure displacements, devices to measure the involved velocities and rainfall spray nozzles systems. Specifically, tensiometers and time-domain reflectometry (TDR) probes to measure suction and soil water content, pressure transducers for pore water pressure, laser sensors and high-resolution video cameras to measure displacements and deformation, respectively in orthogonal and plan direction. The use of two independent channels also makes it possible to analyze the propagation phase and allow the positioning of impact structures so as to evaluate any mitigation strategies.

The flume has a rectangular section along its entire length. The structure, supported by metallic frames, is 1 m-high, 1 m-wide, and 6 m-long and, by means of proper equipment, it is possible to apply different slope angles in two 3 m-long separate sections. The flume can be tilted to any inclination up to 50° (Figure 1).

Besides the scientific utility, such prototypes are particularly useful for all cases that are difficult to monitor with field instruments, since they make it possible to directly observe the behavior both at failure and during the transient phases rarely observed in the field. The possibility of creating and setting up large physical models enables larger soil volumes to be analyzed and a more faithful reproduction of the natural phenomenon, while minimizing boundary effects.

To date, many tests have been developed useful for understanding the processes that underlie the triggering of pyroclastic soils due to rain infiltration, to identify the different response mechanisms to varying soil porosity levels, to define the hydrological characteristics of soils and evaluate the resistance of protection devices against debris flows.

In this project we will make use of this facility, with a minor adaptation consisting in reducing the channel width to 0.6 m, to reproduce large-volume dry granular flows triggered by a release from a newly constructed hopper. Specifically, the experimental program in this project will address the following aspects:

- reproduce scaled natural granular flows through feeding of up to 1 cubic meter of material over a few seconds.

- Analyze the flow behavior as the substrate roughness varies.

- Verify at a large scale the possible generation of pore pressure at the base.

- Validate the simulation procedures present in the literature models.

Compatible with the available time (realistically less than two years), the experimental campaign will be carried out by using natural granular material of constant density specifically purchased for the experiments at monodisperse batches and focusing on the two following parameters and varying them within a feasible range, as indicated below:

- Particles grainsize distribution: we will vary the particle grainsize by exploring mono-, bi-, three-disperse granular mixtures and eventually a complex grainsize distribution (e.g., Weibull). The grain sizes selected for the experiments range from 2 cm to less than 1 mm.

- Substrate roughness: for each tested grainsize or grainsize distribution, we will vary the substrate roughness by gluing solid particles of fixed size on removable carpets. The roughness, defined by the mean diameter of the glued particles, will be varied from 0 (smooth surface) to a size coinciding with that of the coarsest possible particle that can be used in the experiment (about 2 cm).

Each experiment resulting from the combination of the above parameters will be repeated three times to verify the repeatability of the experiments and allow estimating error bars of the measured variables. For performing accurate tests, a device designed for guaranteeing the controlled release of a large volume of granular material flow will be realized. The device will be configured as shown in Figure 2, where the geometries have been defined based on the evaluation and knowledge already reached by the research group. In particular, the basic geometric scheme arises from the considerations that a granular flow is to be fed for a period of about 3-4 seconds at a flow rate of approximately 250-300 kg/s. In these conditions and as a first order approximation, by assuming that the flow rate from the release system is conserved in the channel, an approximately 10 cm-thick flow moving of a few m/s will be produced. To achieve this, it is necessary to have a hopper of at least 1 cubic meter. The planning of the flow rate released was carried out referring to the hopper construction theories reported

We will monitor the flow velocity and thickness space-temporal evolution along the flume by means of an array of sensors, both existing and to be installed during this project (Figure 3). Specifically, we will use:

- six evenly spaced ultrasonic sensors (Banner T30UUPA) for measuring the thickness of the flow.

- Twelve evenly spaced high speed highly sensitive pressure transducers (ICSensors Model 154N) at the bottom of the channel along its axis for measuring the pore pressure.

- An array of digital camera to monitor the bulk flow evolution from the top and one high speed high resolution video camera placed around 4-5 m from the flume inlet parallel to the flume wall in order to record the flow from the bottom to the top, with a particular focus on the fabric of the particles within the flow, their slip velocity at the substrate and the velocity profiles from the substrate to the top of the flow.

- For this project and by using equipment already owned by the research group, a new technique will be implemented for designing and setting-up an image acquisition system, by using a laser scanner in line scan mode. The laser scanner in line scan mode can be used to investigate the morphological variations of the granular flow in a dynamic modality by scanning up to hundreds of lines per second along the flume axis. Some applications in a preliminary study, by using a Riegl VZ 1000 laser scanner, have demonstrated the effectiveness of the method. The use of the laser scanner will allow measuring the space-time evolution of flow thickness and the propagation velocity of the flow body along its axis with a high time resolution.

sensors.

WP1 Milestones

M1a: Setup and adaptation of the system for experimental tests: acquisition of reference sensors for measuring granular flow and pore pressure; selection of the material for different particle grainsize distribution to be used for the tests; realization of the device to reproduce substrate roughness (by month 3, hereafter M3). M1b: design and construction of the hopper for the production of voluminous granular flows (by end of M2 to M6) M1c: adaptation and setup of the laser scanner on granular material samples selected for simulations (by end of M3 to the M5) M1d: Design and realization of the flume tests and check of simulation models (by M6 to M24)

WP1 Deliverables

D1a Technical manual for the use and application of laboratory measurement systems; Technical description of the sensor setup and calibration procedures used. D1b: Technical collection manual and database with the scale details of the testsperformed and the results obtained.

WP2 Improvement and validation of numerical models of geophysical flows (Leader: RU1)

Simultaneous to the WP1 activities, RU1 will conduct numerical modeling of the large-scale granular flows in order to both validate and improve two numerical models currently used to simulate (geophysical) granular flows: MFIX-TFM (http://mfixnetldoegov/) and TITAN2D (https://githubcom/TITAN2D/titan2d, [30]). The former is an Eulerian-Eulerian model which represents the fluid and solids as interpenetrating continua and as such solves the Navier-Stokes equation of each phase in 2 or 3D.

Constitutive equations for the fluid-solid and solid-solid mass, momentum and energy exchanges are available in the solver, as well as models for the interaction between the solid phase and the walls. TITAN2D is a shallow-water model representing the granular flow as a single phase (although later implementations allow using a multi-phase approach) with different options available for the rheological description (Mohr-Coulomb, Pouliquenne-Forterre and Voellmy-Sallm; see [30] and the user manual for more details), each one requiring the specification of rheological model-specific parameters.

RU1 will employ:

- MFIX-TFM in order to investigate on the solid phase-wall boundary conditions and their most accurate parameters (e.g., solid phase velocity gradients at the wall, specularity coefficient [31]) by quantitative comparison between the observed and simulated flow patterns (e.g., particle slip velocity at the wall, velocity profiles perpendicular to the wall) in the area of the flume that will be visually monitored by a video camera (see Figure 3). The comparison will also be carried out between the observed and simulated flow front thickness and velocity space-temporal evolution by means of the cameras’ array and the flow thickness along its axis obtained via the laser scanner. This work will complement the pioneering research by Neglia et al. [16], in particular in the effect of substrate roughness on the solid phase wall boundary condition and with the development of new constitutive laws for the calculation of the boundary condition parameters as a function of the local substrate and flow properties.

- TITAN2D in order to first determine the rheological model that best replicates the experiments' observation and, for each rheological model, the most appropriate parameters and their relationship with experimental conditions (grainsize, roughness, channel slope). The quantitative comparison between results of numerical simulations and observations will be carried out using the bulk flow thickness and velocity as probing parameters. This approach will also shed light on the performance of shallow-water models in replicating the flow stage, since up to this point much of the emphasis has been placed on the runout and the area inundated by the deposit left by the emplacement of the granular flow.

WP2 Milestones

M2a: Implementation of the experimental setup into MFIX (this step for this model includes the development of the computational grid, which requires a numerical study on the independence of the simulation results from the grid resolution) and TITAN2D (M2) M2b: Numerical simulations of the first year of experiments completed (M12) M2c: Numerical simulations of the second year of experiments completed (M22)

WP2 Deliverables

D2a: results of the first numerical simulation tests and computational grid D2b: most appropriate boundary condition, related parameters and their relationship with flow and wall properties for MFIX D2c: most appropriate rheological model, related parameters and their relationship with flow and wall properties for TITAN2D.

WP3 Dissemination of technological development and project outcomes (Leader: RU1 and RU2)

Dissemination of the scientific results of the project is decisive for the success of the proposal in terms of a broader technological development on the matter. Results of the project will be disseminated to the scientific community through the institutional websites of Departments at both involved Universities. A newly created open access and user-friendly website on the project will be created by RU2 at UniCal, where advances of the project will be periodically published. A broader audience will be reached with the sharing of results on newly created social media channels (e.g., Facebook, Twitter, Instagram, Tik Tok) and on a dedicated YouTube channel where to publish videos of experiments held at the RU2 laboratories.

A variety of outcome activities (e.g., press releases, Laboratory Open Days for students, Workshops for young researchers of other institutions/fields, School for PhD students and early-career researchers) will also represent the core of the WP3 of the project.

Project outcomes will be disseminated to the scientific community via publications in indexed and peer-reviewed first-class scientific journals and presentations at national congresses and conferences. Finally, results of the project will be also presented at National and International Departments of Civil Protection, in order to contribute to refining the existing hazard/risk maps for volcanic systems.

WP3 Milestones

M3a: Development of the project website and social media channels (M6); M3b: Dissemination through website and social media channels of results of the first year (M12); M3c: Exploitation of the results of the project to the scientific community and creation of an interdisciplinary experimental network for exchange of data (M22).

WP3 Deliverables

D3a: Publication of the new website and of social channels for sharing the results of the Project. D3b: Organisation of workshops for researchers of other institutions/fields (including National/International Civil Protection Departments) and school for PhD students and early-career researchers during the last six months of the project. D3c: submission of achieved results to peer-reviewed first-class scientific journals and presentation at national congresses and conferences.